Our Capacity

Citizen L32 VIII

7-axis Swiss lathe with sub-spindle operations, High-speed machining with low-frequency vibration cutting, 38mm max dia bar, 3.1m bar feeder, adjustable driven unit (angled holes)

Citizen L20 VIII

7-axis Swiss lathe with sub-spindle operations, High-speed machining with low-frequency vibration cutting, Long Parts Adapter (750mm max), 20mm max dia bar, 3.1m bar feeder, adjustable driven unit (angled holes)

Miyano BNA 42MSY

fixed headstock, twin-spindle machine with one turret that uses simultaneous machining, 42mm max dia bar, 100 mm machining length, 1m bar feeder

DMG Mori EcoMill 50

(3+2 axis) – Advanced 5-axis machining for intricate designs, 800mm dia table, Renishow probe.

Mazak VC530

3-axis Mill with Kitagawar 4th axis unit, over 1000mm in X travel, Renishaw probe.

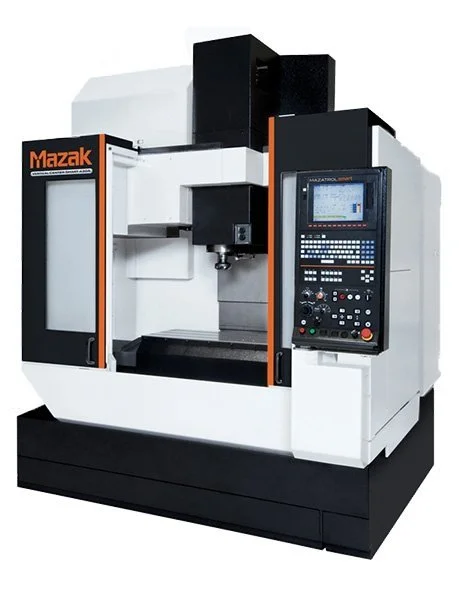

Mazak VC430

3-axis mill, 600mm in X travel, quick and accurate.

2x Doosan Puma GT2100

Reliable performance for larger, more metal removal turning operations, 310mm dia max, 500mm between centres

Doosan DMN500

The DNM 500 handles a wide range of milling tasks, from contouring complex parts to volume production, over 1000mm in X it offers a larger work area for bigger components

Other Equipment

Mitutoyo Shadowgraph

Tesa Hite 700

Fitfactory Tricorn MRP Software

Why Choose Double G Engineering?

With over 50 years of expertise, Double G Engineering Ltd is a trusted name in precision CNC machining. We combine innovation, accuracy, and efficiency to deliver custom-engineered components and high-performance solutions for industries across the UK. Our commitment to quality ensures every part meets the highest standards, making us your reliable partner for modern engineering challenges.